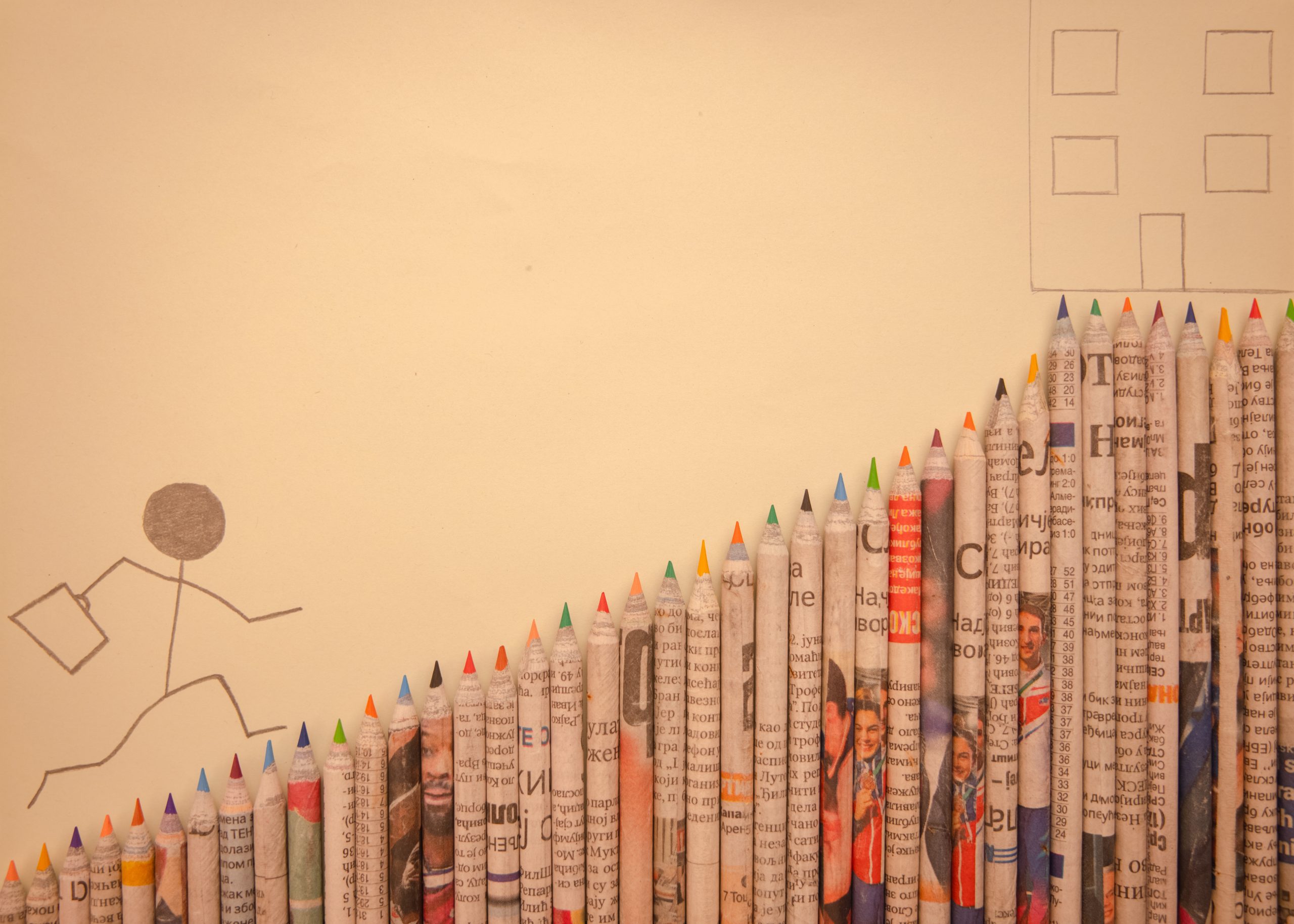

New Pen’s idea to manufacture pencils and coloured pencils using newspapers instead of wood is one of the 16 innovative solutions geared to accelerate the green transition that were supported by the EU within the ‘EU for the Green Agenda in Serbia’ initiative.

The Marković family always had entrepreneurial spirit. After more than 16 years in the service industry, they decided to try their hand in manufacturing. They had various ideas, and then they saw The Odd Life of Timothy Green where one of the characters works at a pencil factory and it dawned on them: “Nobody is making pencils in Serbia, we could do that!”

– Once we started looking into the wooden pencil production process and the kinds of machines we would need, we learned that they made pencils out of old newspapers and recycled paper in China and India. And there was no going back! The very idea of manufacturing something that does not exist anywhere else in Europe and making the process environmentally friendly and appealing grabbed such a hold of us that we tried to find out how it was done for weeks – Marković says, adding that most pencils manufactured in China and India are not entirely environmentally friendly, and they wanted their product to have the highest quality and be 100 percent environmentally friendly and safe.

Having successfully combined creativity and responsibility to the environment, they created their peculiar products – pencils and coloured pencils made of old newspapers.

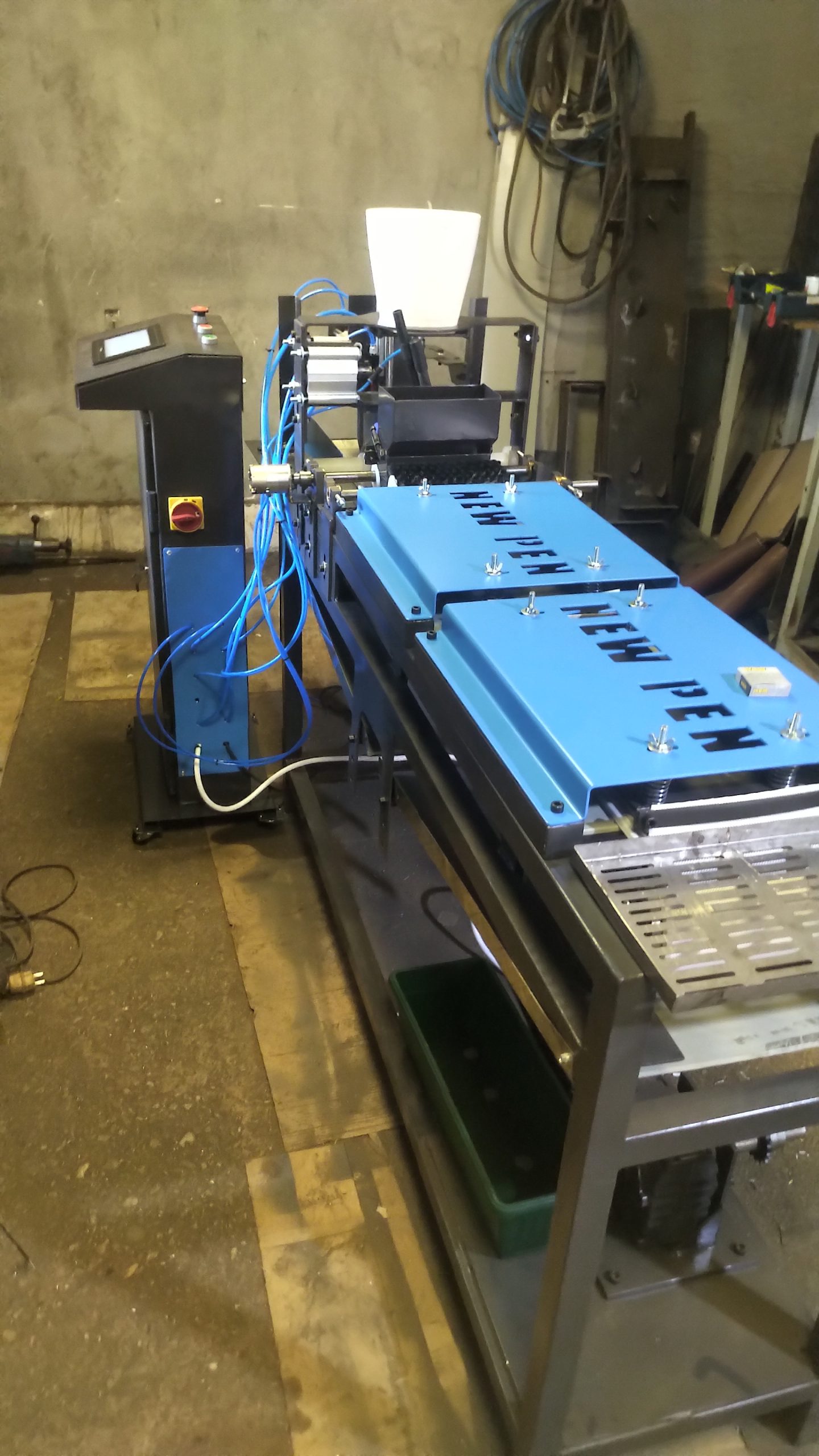

– The production process is not simple at all. It begins with collecting or buying unread newspapers. Then the newspapers are stacked so they can be cut into strips. One newspaper strip is enough to make one pencil or coloured pencil. Then comes the slowest part of the work, which is hand-pasting the graphite core into each strip. Then the newspaper strip and the core are rolled into a pencil in a semi-automatic machine. – Marković explains.

Thanks to the support they received as part of the “EU Green Agenda in Serbia” initiative, two new automatic machines are being constructed that will accelerate the pencil rolling process.

The next item in the production process is drying. Initially, we purchased three ovens to dry pencils, but we discovered that they consume excessive electricity. Consequently, we devised a system for natural drying, which varies depending on the season and takes a maximum of two days. Following the drying phase, we proceed to cut the pencils to ensure they are all of equal length. Once the cutting is complete, it is time for quality control of each pencil and crayon before packing them into boxes, Marković revealed.

This production method enabled them to make 3000-3500 pencils per day, and they procure all of their raw materials apart from graphite in Serbia.

Marković does not make it a secret that there were many challenges initially – from procuring materials, testing them, down to the production stage, since no one on the team was trained for this line of work. Although they did not know many aspects initially, their persistent work resulted in a product they are truly proud of. From the beginning they were positive that they would not give up on their commitment to environmental protection. This is why they are constantly developing new ideas so they can completely round up their production process and be waste free.

– In parallel with the environmental development in our production process, we also work on raising awareness on the relevance of environmental protection. Our vision is to reach as many people we can, especially the youngest generations, who would embrace not only our products, but also our principle and environmentalist ideas. We hope our example will incentivise others to engage with this topic more and to try to contribute in line with their individual capacities – Dragan Marković concludes.

The new Challenge for Innovative Solutions for the Green Transition was announced in February this year and will remain open until the end of 2026, with the goal of supporting innovative solutions in all five areas of the Green Agenda for the Western Balkans.

The ‘EU for Green Agenda in Serbia’ project, technically and financially supported by the European Union and implemented – in partnership with the Ministry of Environmental Protection – by UNDP, in cooperation with the Embassy of Sweden and the European Investment Bank (EIB), with additional funding provided by Governments of Sweden, Switzerland, and Serbia.

Photo: New Pen